Xsg Flash Dryer for Zincborate

Basic Info

Model No.: XSG

Product Description

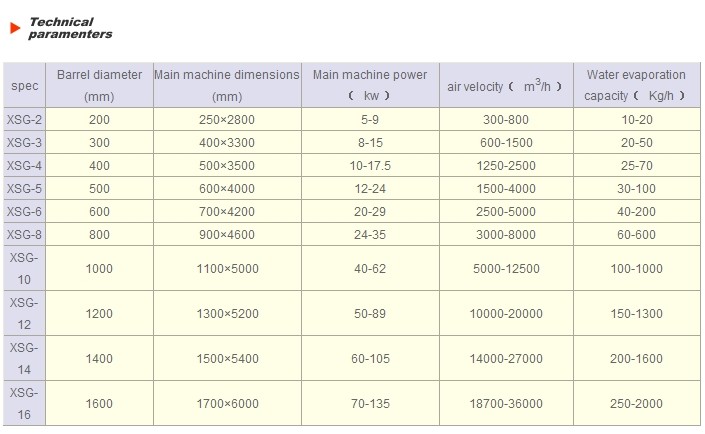

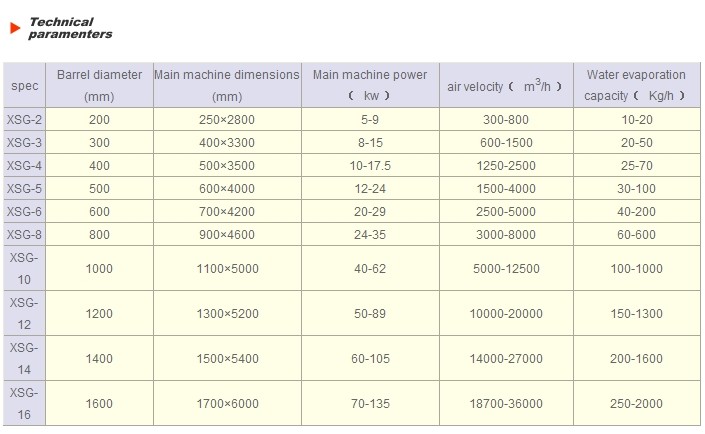

Model NO.: XSG Finished Dosage Form: Granules Produce Certificate: ISO9001&14001 Specification: XSG-200, XSG-300, XSG-800, XSG-1600, XSG-1650 HS Code: 8419399090 Type: Pharmaceutical Milling Machinery Certification: ISO Trademark: YiBu Origin: China XSG flash dryer for zincborate

Descriptions:

Absorbed the foreign advanced equipment and technology, our factory and

Shenyang Chemical Research Institute under the Chemical Ministry of the State has developed this machine. This is a new kind of Drying equipment used for drying the materials, such as paste state, thixotropy, thermal sensitive powder and particles. Our factory ID equipped with the test sample machine, which can be used for carrying out the drying tests of various feeds for our users and for to provide the parameters to select the applicable machine.

Principle:

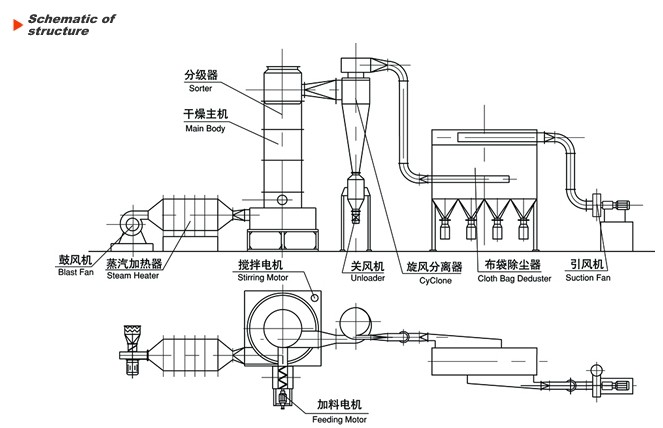

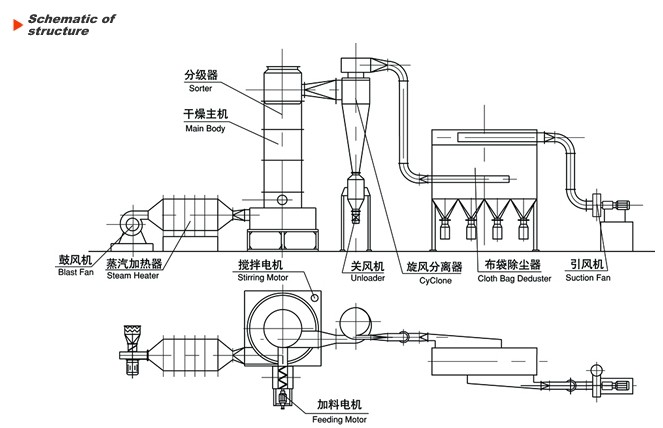

The hot air enters into the bottom of the drier in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. The paste state materials enter into the drier through the screw charger. Under the powerful function of the sitting vanes at high-speed rotation, the materials are distributed under the function of strike, friction and shearing force. The block state materials will soon be smashed and contact the hot air fully and the materials are heated and dried. The dried materials after the de-watering will go up with the heat-air flow. The step rings will stop and keep the big particles. Small particles will be discharged out of the drier from the of the equipment by centrifugal force function and be smashed again after they fall down to the bottom.

Features:

This machine combines the whirl technology with the fluidity ejection and smashing step technologies. The equipment is compact and small in size, high in production efficiency and continuous in the production. It has realized that a small equipment can perform the large production.

The drying capacity for this machine is big but its energy consumption is low. Its hear efficiency can go up to more than 70%. The material star time is very short. The quality of the final products is very good. The machine can be used for drying the hest sensitive materials. For the negative pressure or the micro-negative pressure operation, the machine is good for its tightness and high in the efficiency so as to eliminate the environmental pollution. Contact us if you need more details on Drying Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Spin Flash Dryer、Flash Dryer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Descriptions:

Absorbed the foreign advanced equipment and technology, our factory and

Shenyang Chemical Research Institute under the Chemical Ministry of the State has developed this machine. This is a new kind of Drying equipment used for drying the materials, such as paste state, thixotropy, thermal sensitive powder and particles. Our factory ID equipped with the test sample machine, which can be used for carrying out the drying tests of various feeds for our users and for to provide the parameters to select the applicable machine.

Principle:

The hot air enters into the bottom of the drier in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. The paste state materials enter into the drier through the screw charger. Under the powerful function of the sitting vanes at high-speed rotation, the materials are distributed under the function of strike, friction and shearing force. The block state materials will soon be smashed and contact the hot air fully and the materials are heated and dried. The dried materials after the de-watering will go up with the heat-air flow. The step rings will stop and keep the big particles. Small particles will be discharged out of the drier from the of the equipment by centrifugal force function and be smashed again after they fall down to the bottom.

Features:

This machine combines the whirl technology with the fluidity ejection and smashing step technologies. The equipment is compact and small in size, high in production efficiency and continuous in the production. It has realized that a small equipment can perform the large production.

The drying capacity for this machine is big but its energy consumption is low. Its hear efficiency can go up to more than 70%. The material star time is very short. The quality of the final products is very good. The machine can be used for drying the hest sensitive materials. For the negative pressure or the micro-negative pressure operation, the machine is good for its tightness and high in the efficiency so as to eliminate the environmental pollution. Contact us if you need more details on Drying Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Spin Flash Dryer、Flash Dryer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Air Steam Dryer

Premium Related Products

Other Products

Hot Products

Fg Vertical Fluidizing Bed DryerSzg Double Cone Vacuum DryerDmh Double Door Dry Sterilization OvenProfessional Centrifugal Spray Dryer MamufacturerMonosodium glutamate vibrating fluid bed dryerGrain flash dryerKJG Series hollow blade dryer for cassava flourZLG vibrating fluid bed dryerXSG spin flash drying machineDehydration belt dryerDw continuous Mesh -Belt Dryer for Vegetable &fruitsDW Mesh Belt Dryer Machinemesh belt dryerLPG Thickening agent spray dryerLPG herb ointment spray drier spray dryerLPG size centrifuge spray dryer machine