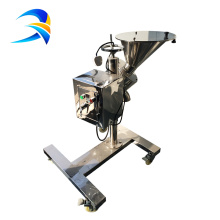

Fluiding Bed Drying Granulator for Pharma

Basic Info

Model No.: FL

Product Description

Model NO.: FL Finished Dosage Form: Granules Customized: Customized Warranty: 1 Year Good Price: Experienced After Sale Service Specification: FL Type: Crude Drug Equipment Certification: GMP, ISO Condition: New Professional Manufacturering: Strong Technical Power Transport Package: Standard Wooden Case Origin: China Pharma Fluidized Drying Granulator

Description

Granulation is a process of transforming the powder particles into ideal, uniform and porous spherical articles. The powdery particles are annulus fluidized in the material container of the fluidized Granulating machine. Some particles form into pellets containing adhesives after being mixed and preheated by purified heating air and mixing with atomized binder solution. Being dehydrated by the hot air, the water evaporated from the pellets and the adhesives freeze.

Application

FL fluidized drying granulator is widely used in producing tablet granules, granules and capsules granules in pharmaceutical industry and for cocoa, coffee, milk, juice of granule, and flavoring in food industry. Additionally, this fluidized granulating machine is suitable for palletizing in pesticides, fertilizer, pigment, dyestuff as well as coating granules, pill protecting layer, available colors, release, film and enteric.

Features

1. FL fluidized drying granulator through powder granulation improves the mobility and solubility as well as reduces the flying dusts.

2. The mixing, granulation and drying can be completed in the same fluidized granulating machine.

3. The antistatic filter cloth is used to ensure the security of equipment operation.

4. This fluidized drying granulator adopts pressure relief holes to ensure the safety of the facility and staff in case of the explosion.

5. Our fluidized granulating machines are without any dead angle as well as easy to load and unload materials.

6. This granulating equipment is easy to wash, conforming to the GMP standard.

Parameters of Fluidized Drying Granulator

Contact us if you need more details on Pharma Fluidized Bed Drying Granulator. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pharma Fluid Bed Granulator、Fluidizing Drying Granulator for Pharma. If these products fail to match your need, please contact us and we would like to provide relevant information.

Description

Granulation is a process of transforming the powder particles into ideal, uniform and porous spherical articles. The powdery particles are annulus fluidized in the material container of the fluidized Granulating machine. Some particles form into pellets containing adhesives after being mixed and preheated by purified heating air and mixing with atomized binder solution. Being dehydrated by the hot air, the water evaporated from the pellets and the adhesives freeze.

Application

FL fluidized drying granulator is widely used in producing tablet granules, granules and capsules granules in pharmaceutical industry and for cocoa, coffee, milk, juice of granule, and flavoring in food industry. Additionally, this fluidized granulating machine is suitable for palletizing in pesticides, fertilizer, pigment, dyestuff as well as coating granules, pill protecting layer, available colors, release, film and enteric.

Features

1. FL fluidized drying granulator through powder granulation improves the mobility and solubility as well as reduces the flying dusts.

2. The mixing, granulation and drying can be completed in the same fluidized granulating machine.

3. The antistatic filter cloth is used to ensure the security of equipment operation.

4. This fluidized drying granulator adopts pressure relief holes to ensure the safety of the facility and staff in case of the explosion.

5. Our fluidized granulating machines are without any dead angle as well as easy to load and unload materials.

6. This granulating equipment is easy to wash, conforming to the GMP standard.

Parameters of Fluidized Drying Granulator

| Model | FL-3 | FL-5 | FL-15 | FL-30 | FL-60 | FL-120 | FL-200 | FL-300 | FL-500 | |||||||

| Material Container | Volume (L) | 12 | 22 | 45 | 100 | 220 | 120 | 670 | 1000 | 1500 | ||||||

| Diameter (mm) | 300 | 400 | 550 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | |||||||

| Production Capacity | Minimum (kg) | 1.5 | 4 | 10 | 15 | 30 | 80 | 100 | 150 | 200 | ||||||

| Maximum (kg) | 4.5 | 6 | 20 | 45 | 90 | 160 | 300 | 450 | 750 | |||||||

| Fan | Air Volume (m3/h) | 1000 | 1200 | 1400 | 1800 | 3000 | 4500 | 6000 | 7000 | 8000 | ||||||

| Power (kw) | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 | 30 | 45 | |||||||

| Steam Consumption (kg/h) | 15 | 23 | 42 | 70 | 141 | 221 | 282 | 366 | 451 | |||||||

| Compressed Air Consumption (m3/h) | 0.9 | 0.9 | 0.9 | 0.9 | 1.0 | 1.0 | 1..1 | 1.5 | 1.5 | |||||||

| The Weight of Main Engine (kg) | 500 | 700 | 900 | 1000 | 1100 | 1300 | 1500 | 1800 | 2000 | |||||||

| Steam Pressure (Mpa) | 0.3 to 0.6 | |||||||||||||||

| Operative Temperature (ºC) | Adjustable from room temperature to 120ºC | |||||||||||||||

| Operation Time (min) | According the characteristic of material from 45 to 90 | |||||||||||||||

| Yield of Products (%) | ≥ 99 | |||||||||||||||

| Noise dB (A) | The fan and the main engine are separately installed, noise ≤ 75dB | |||||||||||||||

| External Dimension of the Main Engine (L×W×H) (m) | 1.0 × 0.6 × 2.1 | 1.2 × 0.7 × 2.1 | 1.25 × 0.9 × 2.5 | 1.6 × 1.1 × 2.5 | 1.85 × 1.4 × 3 | 2.2 × 1.65 × 3.3 | 2.34 × 1.7 × 3.8 | 2.8 × 2.0 × 4.0 | 3 × 2.25 × 4.4 | |||||||

Product Categories : Granulating machine

Premium Related Products

Other Products

Hot Products

Fg Vertical Fluidizing Bed DryerSzg Double Cone Vacuum DryerDmh Double Door Dry Sterilization OvenProfessional Centrifugal Spray Dryer MamufacturerMonosodium glutamate vibrating fluid bed dryerGrain flash dryerKJG Series hollow blade dryer for cassava flourZLG vibrating fluid bed dryerXSG spin flash drying machineDehydration belt dryerDw continuous Mesh -Belt Dryer for Vegetable &fruitsDW Mesh Belt Dryer Machinemesh belt dryerLPG Thickening agent spray dryerLPG herb ointment spray drier spray dryerLPG size centrifuge spray dryer machine