Mineral Drying Machine in Rotary Drying Equipment

Basic Info

Model No.: HG-2.8x6

Product Description

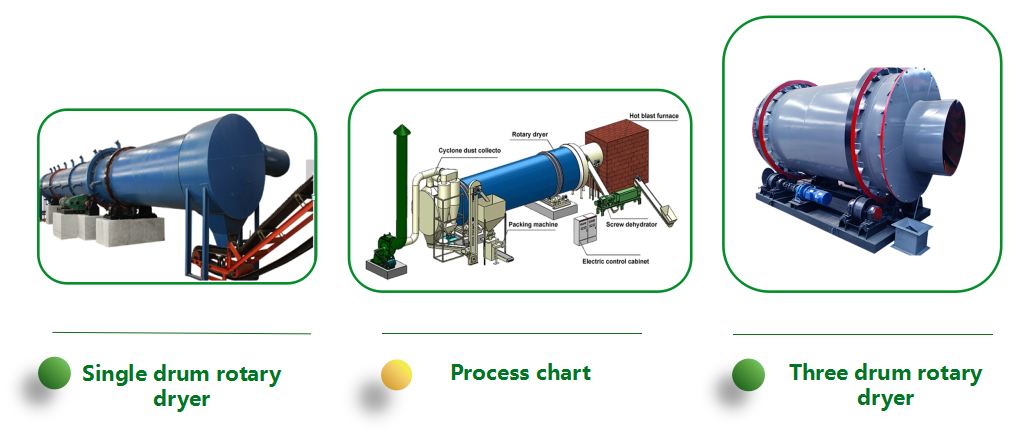

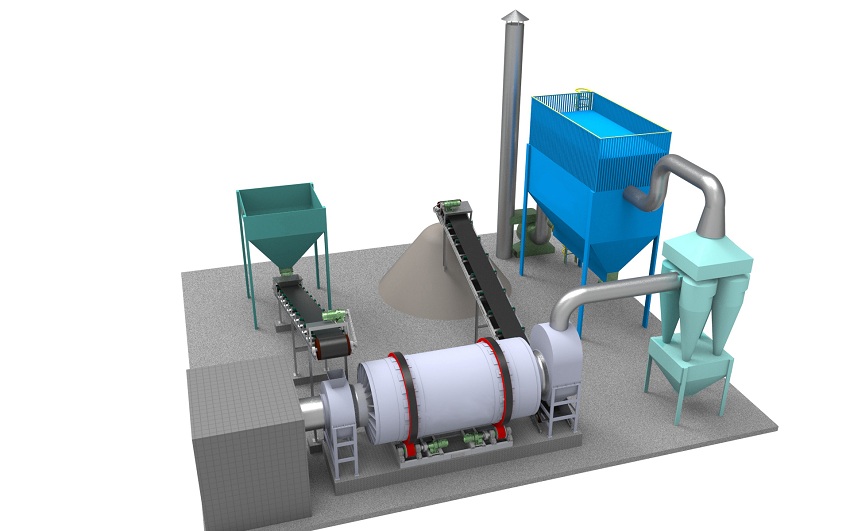

Minerals produced in the mining industry, such as ore, quartz sand and iron ore, need to be dried before they can be used in practical applications. The equipment for drying this mineral is called a mineral Drying Machine. Mineral Drying equipment belongs to rotary dryer, which is divided into single drum dryer and three drums dryer according to its working principle. Through continuous innovation and experiment, the rotary dryer produced by our company adopts the downstream method on the original basis, which achieves better drying effect and effectively reduces energy consumption.

Mineral drying machine in Rotary Drying Equipment

Description:

Rotary dryer, also called rotating cylinder Drying machine, which is mainly used for mineral processing, building materials, metallurgy, chemical, cement industry and other departments drying certain wet degree or the size of material. Rotary dryer is mainly consisting of rotary body, raw material feeding plate, driving and supporting device, etc. Rotary dryer strong adaptability to raw materials can be drying a variety of materials, and the equipment is simple and reliable, so widely used. It is of high efficiency and has the features of reasonable structure, high capacity, low consumption easy operation, etc. It can make final products free from dirt and impurities and reduce the high quality sand loss.

Parameters:

Model HG-2.8x6 Shell diameter (mm) 2800 Shell length (mm) 6000 Shell volume (m3) 36.9 Rotary speed (r/min) 3-10 Power(kw) 5.5*4 Capacity(t/h) 15-35

Features:

a.It can use chemical gypsum (Free gypsum dehydration, phosphogypsum etc) to fry β-semi-water gypsum directly.

b.From craft process, guarantee the requests of frying temperature and time which should make precise control in roasting the gypsum.

c.The discharging of work machine is designed rationally, when operation, there is no dust pollution.

d.When interval feeding and discharging, it can be banked fire and shut down furnace. The stove fire can be put into normal production after 3 minutes by again opening furnace.

e.Matched gas stove or fluidized bed furnace is used for supplying heat, the waste heat of tail gas can be used recycling.

Flow chart:

FAQ:

1. How to pay to you ?

We can accept 30% deposit , and balance paid to us before delivery machine to you .

2. How long is the delivery time?

For standard machines or Components, it would be 2-7 days; For non-standard machines and customized machines according to clients

specific requirements, it would be Appointment time.

3. Do you arrange shipment for the machines?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.The nearest port to us is Qingdao Port.

4. How about your product after-sales service?

Normally we provide video and written technical support. If necessary, our engineers can also provide on-site service.Our product accessories can be selected according to the actual needs of the customer to choose the most appropriate way to deliver.

Contact us if you need more details on Mineral Drying Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Rotary Drying Equipment、Industrial Mineral Drying Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Rotary Dryer > Mining Drying Machine