Xf Fluidized Dryer Machine

Basic Info

Model No.: XF

Product Description

Model NO.: XF Operational Method: Continuous Drying Medium: Air Heating Mode: Convective Type of Flow: Cross Flow Good Price: Experienced After Sale Service Specification: XF HS Code: 841939 Structure: Fluidized Bed Drier Operation Pressure: Atmospheric Dryer Appearance of Dried Sample: Bulk Movement Way: Fluidizing Professional Manufacturering: Strong Technical Power Trademark: Yuzhou Origin: China XF Fluidized Dryer

Description

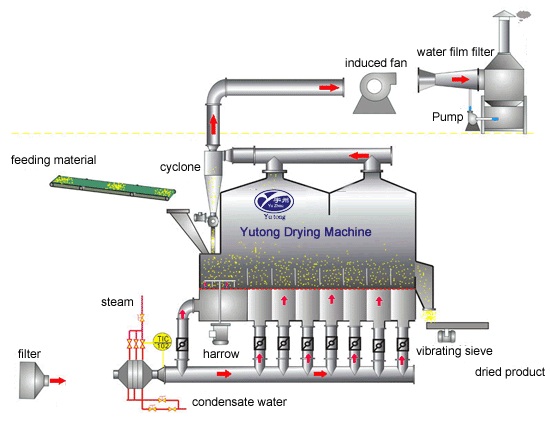

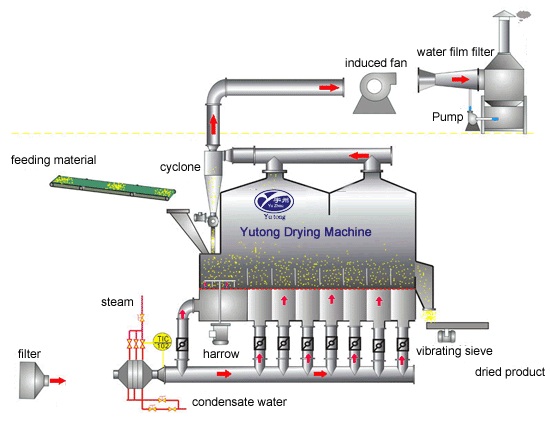

Boiling Drying Machine, also called fluidized bed dryer, plays an important role in pharmaceutical, chemical, food and grain processing. XF fluidizing dryer is composed of air filter, fluidized bed, cyclone separator, bag-type dust collector, high-pressure centrifugal fan and console. The hot air enters into the fluidized bed through a valve plate, and the wet materials come into fluidization state. The materials extensively contact with the hot air and the heat transfer process is increased, so that the boiling drying machine can dry the materials in a short time. The materials enter into from one side of the bed, after fluidized drying for several seconds to minutes, they will automatically discharge from the other side of the bed. The exhaust gas is expelled from the top of the fluidized bed.

Application

XF fluidized bed dryer is appropriate for drying granular materials, such as crude drug, tablet granule, traditional Chinese dissolved medicines, plastic resin, citric acid, corn germ, feed and other powdery and particle materials. The optimum particle size ranges from 0.5 mm to 3 mm.

Features

1. XF boiling Drying machine can implement batch production or continuous operation. It also can realize automatic production.

2. Fast drying speed and low temperature can ensure the quality of the fluidized bed dryer. This drying machine meets the GMP standards.

3. Steam, electricity and hot air furnace can be used as the hot source.

4. XF boiling drying machine uses nitrogen instead of oxygen as the carrier, which can effectively prevent oxidation and retain protein component. It also can recover organic solvent and can be used for drying, cooling and granulating flammable and explosive materials.

Flow Chart of XF Fluidized Bed Dryer

Parameters of Boiling Drying Machine

Notes:

1. Drying capacity will be affected by material property, solid content and inlet and outlet temperature.

2. A refers to cyclone dust collector, B refers to built-in type.

Contact us if you need more details on Fluidied Bed Dryer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Fluid Bed Dryer Machine、Fluidizing Drying equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Description

Boiling Drying Machine, also called fluidized bed dryer, plays an important role in pharmaceutical, chemical, food and grain processing. XF fluidizing dryer is composed of air filter, fluidized bed, cyclone separator, bag-type dust collector, high-pressure centrifugal fan and console. The hot air enters into the fluidized bed through a valve plate, and the wet materials come into fluidization state. The materials extensively contact with the hot air and the heat transfer process is increased, so that the boiling drying machine can dry the materials in a short time. The materials enter into from one side of the bed, after fluidized drying for several seconds to minutes, they will automatically discharge from the other side of the bed. The exhaust gas is expelled from the top of the fluidized bed.

Application

XF fluidized bed dryer is appropriate for drying granular materials, such as crude drug, tablet granule, traditional Chinese dissolved medicines, plastic resin, citric acid, corn germ, feed and other powdery and particle materials. The optimum particle size ranges from 0.5 mm to 3 mm.

Features

1. XF boiling Drying machine can implement batch production or continuous operation. It also can realize automatic production.

2. Fast drying speed and low temperature can ensure the quality of the fluidized bed dryer. This drying machine meets the GMP standards.

3. Steam, electricity and hot air furnace can be used as the hot source.

4. XF boiling drying machine uses nitrogen instead of oxygen as the carrier, which can effectively prevent oxidation and retain protein component. It also can recover organic solvent and can be used for drying, cooling and granulating flammable and explosive materials.

Flow Chart of XF Fluidized Bed Dryer

Parameters of Boiling Drying Machine

| Model | Bed Area (m2) | Drying Capacity (H2O kg/h) | Fan Powder (kw) | Air Pressure (Pa) | Air Flow (m3/h) | Inlet Air Temperature (°C) | Outlet Air Temperature (°C) | Steam Consumption (kg/h) | Power Consumption (kw) |

| XF10A | 0.25 | 10 to 15 | 5.5 | 4900 | 2300 | 60 to 200 | 40 to 80 | 50 | 30 |

| XF10B | 4 | 3800 | 2300 | ||||||

| XF10A | 0.5 | 20 to 25 | 7.5 | 5000 | 3100 | 100 | 60 | ||

| XF10B | 5.5 | 3500 | 3100 | ||||||

| XF10A | 1.0 | 30 to 45 | 15 | 6000 | 4200 | 150 | 90 | ||

| XF10B | 11 | 4700 | 4200 | ||||||

| XF10A | 2.0 | 50 to 80 | 22 | 7400 | 6000 | 250 | 150 | ||

| XF10B | 18.5 | 5900 | 6000 |

Notes:

1. Drying capacity will be affected by material property, solid content and inlet and outlet temperature.

2. A refers to cyclone dust collector, B refers to built-in type.

Contact us if you need more details on Fluidied Bed Dryer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Fluid Bed Dryer Machine、Fluidizing Drying equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Drying machine > Others Drying machine

Premium Related Products

Other Products

Hot Products

Fg Vertical Fluidizing Bed DryerSzg Double Cone Vacuum DryerDmh Double Door Dry Sterilization OvenProfessional Centrifugal Spray Dryer MamufacturerMonosodium glutamate vibrating fluid bed dryerGrain flash dryerKJG Series hollow blade dryer for cassava flourZLG vibrating fluid bed dryerXSG spin flash drying machineDehydration belt dryerDw continuous Mesh -Belt Dryer for Vegetable &fruitsDW Mesh Belt Dryer Machinemesh belt dryerLPG Thickening agent spray dryerLPG herb ointment spray drier spray dryerLPG size centrifuge spray dryer machine